Austempering Time and Its Influence on the Mechanical Performance of Inverse Bainite: Insights from Hardness, Toughness, and Strength Testing

Keywords:

Inverse Bainite, Austempering Time, Hardness, Impact Strength, Mechanical PropertiesAbstract

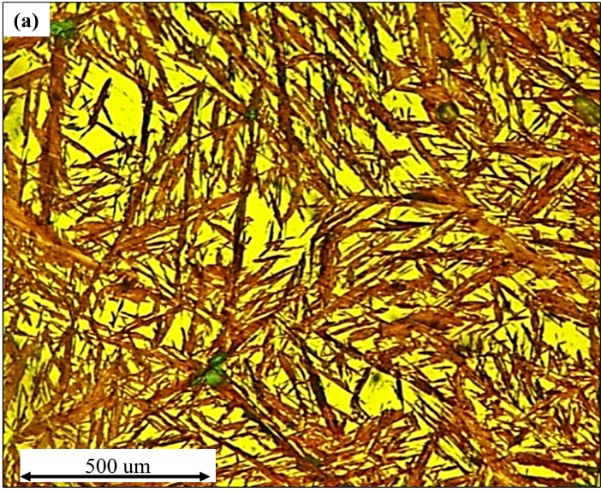

This study examines the impact of austempering time on the mechanical properties of 0.8C experimental steel with inverse bainitic microstructures. Samples were austenitized at 900 °C and austempered at 420 °C for 30, 60, 90, and 120 minutes. The effects on hardness, impact toughness, and (UTS) were analyzed. Microstructural evaluations by optical microscope, scanning electron microscope, and energy dispersive spectroscopy confirmed the formation of inverse bainite. Mechanical testing showed that increasing austempering time leads to higher hardness due to cementite lath growth and reduced ferrite content, but also results in lower Charpy impact energy, indicating reduced toughness. While UTS initially decreases, it increases sharply after 120 minutes, accompanied by brittle fracture. This study suggests that prolonged austempering enhances hardness and strength but increases brittleness, making these structures less suitable for applications involving sudden forces.

References

M. Hillert, “The role of interfacial energy during solid-state phase transformations,” Jernkontorets Ann., vol. 141, pp. 757–789, 1957.

H. I. Kinsman, K.R., Aaronson, “The inverse bainite reaction in hypereutectoid Fe-C alloys.,” Metall. Trans., vol. 1, pp. 1485–1488, 1970, doi: https://doi.org/10.1007/BF02900291.

A. H. I. Lee, H.J., G. Spanos, G.J. Shiflet, “Mechanisms of the bainite (non-lamellar eutectoid) reaction and a fundamental distinction between the bainite and pearlite (lamellar eutectoid) reactions,” Acta Metall., vol. 36, no. 4, pp. 1129–1140, 1988, doi: https://doi.org/10.1016/0001-6160(88)90166-6.

S. M. H. Ishtiaq Muhammad, Aqil Inam, Hassan Munir, “Development and characterization of lower, upper, and inverse bainite in an experimental 0.8wt.% C steel,” J. Pakistan Inst. Chem. Eng., vol. 51, no. 2, 2024, doi: 10.54693/piche.05225.

A. S. Helio Goldenstein, J.A.B. Cifuentes, “Non classical eutectoid decomposition products morphologies in Fe-Cr-C and Fe-Cr-Mo-C steels,” Solid-Solid Phase Transform. Inorg. Mater., 2005.

H. G. & J. A. Cifuentes, “Overall kinetics and morphology of the products of austenite decomposition in a Fe-0.46 Pct C-5.2 Pct Cr alloy transformed isothermally above the bay,” Metall. Mater. Trans. A, vol. 37, pp. 1747–1755, 2006, doi: https://doi.org/10.1007/s11661-006-0117-8.

Y. W. & L. L. Rangasayee Kannan, “Microstructural Evolution of Inverse Bainite in a Hypereutectoid Low-Alloy Steel,” Metall. Mater. Trans. A, vol. 48, pp. 6038–6054, 2017.

K. S. Abbaszadeh Khodamorad, Saghafian Hassan, “Effect of Bainite Morphology on Mechanical Properties of the Mixed Bainite-martensite Microstructure in D6AC Steel,” J. Mater. Sci. Technol., vol. 28, no. 4, pp. 336–342, 2012, doi: https://doi.org/10.1016/S1005-0302(12)60065-6.

c. H. Y. &H. K. D. H. Bhadeshia, “Strength of mixtures of bainite and martensite,” Mater. Sci. Technol., vol. 10, no. 3, pp. 209–214, 1994, doi: https://doi.org/10.1179/mst.1994.10.3.209.

P. K. & A. Borgenstam, “Eutectoid Transformations in 4.12 Mass Pct Cr 0.88 Mass Pct C Steel,” Metall. Mater. Trans. A, vol. 42, pp. 3941–3951, 2011, doi: https://doi.org/10.1007/s11661-011-0794-9.

M. G. M. S. P.-D. R. & J. S. F. P. C. Goulas Ph.D. Candidate, “Bainite Formation in Medium-Carbon Low-Silicon Spring Steels Accounting for Chemical Segregation,” Metall. Mater. Trans. A, vol. 47, pp. 3077–3087, 2016, doi: https://doi.org/10.1007/s11661-016-3418-6.

Y. W. & L. L. Rangasayee Kannan, “A dilatometric analysis of inverse bainite transformation,” J. Mater. Sci., vol. 53, pp. 3692–3708, 2018, doi: https://doi.org/10.1007/s10853-017-1752-8.

S. V. M. & L. N. B. V. V. Malakhov, A. N. Yartsev, T. A. Buyanskaya, “Use of hypereutectoid high-speed steel 11M5F for the production of cutting and cold-stamping tools in the Avtovaz Joint-Stock Company,” Met. Sci. Heat Treat., vol. 39, pp. 186–189, 1997, doi: https://doi.org/10.1007/BF02467281.

J. G. & L. H. Zhihui Chen, “Bainite Transformation Characteristics of High-Si Hypereutectoid Bearing Steel,” Metallogr. Microstruct. Anal., vol. 7, pp. 3–10, 2018, doi: https://doi.org/10.1007/s13632-017-0410-5.

C. C. Kui Chen, Zhouhua Jiang, Liu Fubin, Jia Yu, Li Yang, Wei Gong, “Effect of quenching and tempering temperature on microstructure and tensile properties of microalloyed ultra-high strength suspension spring steel,” Mater. Sci. Eng. A, vol. 766, p. 138272, 2019, doi: https://doi.org/10.1016/j.msea.2019.138272.

F. Q. Ze-Ju Bao1, Hong-Yu Yang , Bai-Xin Dong , Fang Chang , Chuan-De Li , Ying Jiang, Liang-Yu Chen, Shi-Li Shu , Qi-Chuan Jiang, “Development Trend in Composition Optimization, Microstructure Manipulation, and Strengthening Methods of Die Steels under Lightweight and Integrated Die Casting,” Mater., vol. 16, no. 18, p. 6235, 2023, doi: 10.3390/ma16186235.

D. M. Fras, Teresa, Christian C. Roth, “Fracture of high-strength armor steel under impact loading,” Int. J. Impact Eng., vol. 111, pp. 147–164, 2018, doi: https://doi.org/10.1016/j.ijimpeng.2017.09.009.

J. D. Su, Y., S. Yang, X.F. Yu, C.B. Zhou, Y.B. Liu, X.C. Feng, Q. Zhao, Wu, “Effect of Austempering Temperature on Microstructure and Mechanical Properties of M50 Bearing Steel,” J. Mater. Res. Technol., vol. 20, pp. 4576–4584, 2022, doi: https://doi.org/10.1016/j.jmrt.2022.09.002.

J. Zhao, “Effects of austempering temperature on bainitic microstructure and mechanical properties of a high-C high-Si steel,” Mater. Sci. Eng. A, vol. 742, pp. 179–189, 2019, doi: https://doi.org/10.1016/j.msea.2018.11.004.

D. B. S. J. A. Cruz Jr., T. F. M. Rodrigues, V. D. C. Viana, H. Abreu, “Influence of Temperature and Time of Austempering Treatment on Mechanical Properties of SAE 9254 Commercial Steel,” Steel Res. Int., vol. 83, no. 1, pp. 22–31, 2012, doi: https://doi.org/10.1002/srin.201100174.

Q. Y. & X. C. Man Liu, Guang Xu, Jun-yu Tian, “Effect of austempering time on microstructure and properties of a low-carbon bainite steel,” Int. J. Miner. Metall. Mater., vol. 27, pp. 340–346, 2020, doi: https://doi.org/10.1007/s12613-019-1881-y.

Y. W. & L. L. Rangasayee Kannan, “Identification of Inverse Bainite in Fe-0.84C-1Cr-1Mn Hypereutectoid Low Alloy Steel,” Metall. Mater. Trans. A, vol. 48, pp. 948–952, 2017, doi: https://doi.org/10.1007/s11661-016-3924-6.

J. G. A. R. Marder, “Phase Transformations in Ferrous Alloys,” Metall. Soc. AIME, p. 411, 1984.

A. K. W, “Empirical formulae for the calculation of some transformation temperatures,” J. Iron Steel Inst., vol. 203, no. 7, pp. 721–727, 1965.

A. S. & J. Å. Annika Borgenstam, Peter Hedström, Mats Hillert, Peter Kolmskog, “On the Symmetry Among the Diffusional Transformation Products of Austenite,” Metall. Mater. Trans. A, vol. 42, pp. 1558–1574, 2011, doi: https://doi.org/10.1007/s11661-010-0539-1.

G. H. G.G. Ribamar, J.D. Escobar, A. Kwiatkowski da Silva, N. Schell, J.A. Ávila d, A.S. Nishikawa, J.P. Oliveira, “Austenite carbon enrichment and decomposition during quenching and tempering of high silicon high carbon bearing steel,” Acta Mater., vol. 247, p. 118742, 2023, doi: https://doi.org/10.1016/j.actamat.2023.118742.

L. L. Rangasayee Kannan , Yiyu Wang , Jonathan Poplawsky , Sudarsanam Suresh Babu, “Cascading phase transformations in high carbon steel resulting in the formation of inverse bainite: An atomic scale investigation,” Sci Rep, vol. 9, no. 1, p. 5597, 2019, doi: 10.1038/s41598-019-42037-9.

S. T. Watanabe, Tadao, “Toughening of brittle materials by grain boundary engineering,” Mater. Sci. Eng. A, vol. 387–389, pp. 447–455, 2004, doi: https://doi.org/10.1016/j.msea.2004.01.140.

K. K. Takashi Matsuno, Tomohiko Hojo, Ikumu Watanabe, Ayumi Shiro, Takahisa shobu, “Tensile deformation behavior of TRIP-aided bainitic ferrite steel in the post-necking strain region,” Sci. Technol. Adv. Mater. Methods, vol. 1, no. 1, pp. 56–74, 2021, doi: https://doi.org/10.1080/27660400.2021.1922207.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 50SEA

This work is licensed under a Creative Commons Attribution 4.0 International License.