Evaluation of Thermal Mixing in T-Junctions Using Computational Fluid Dynamics (CFD)

Keywords:

T-junction, Thermal Mixing, Computational Fluid Dynamics (CFD), Turbulent Flow, Heat transfer, ANSYSAbstract

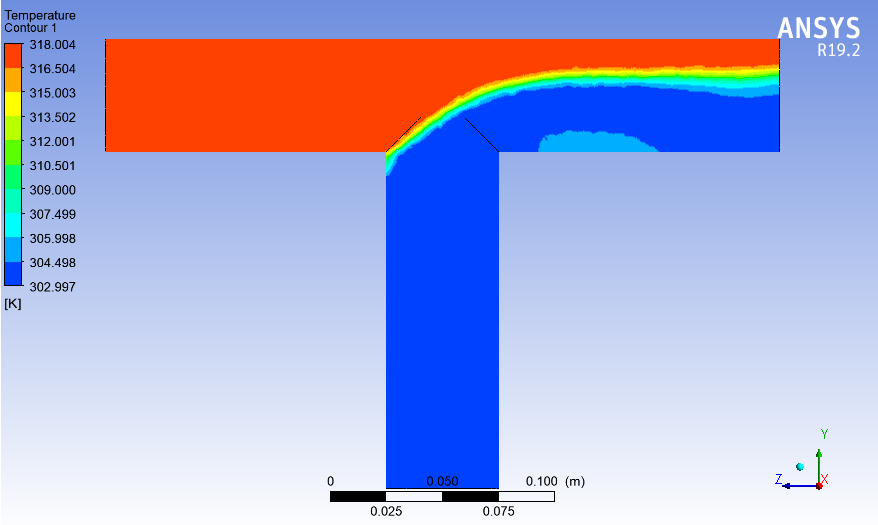

The thermal mixing process in T-junctions presents a significant challenge in optimizing heat transfer and temperature distribution, especially in systems involving both hot and cold fluids. The problem addressed in this study was to understand how variations in inlet velocities, pipe diameters, flow rates, and turbulence models affect heat transfer and thermal mixing. The solution was achieved by performing detailed CFD simulations, evaluating these factors under controlled boundary conditions of 40 m/s hot inlet velocity, 30 m/s cold inlet velocity, and a 15 K temperature difference between the main and branch pipes. The results reveal that higher inlet velocities enhance thermal mixing, with outlet temperatures increasing from 223.382 K to 325.975 K as hot inlet velocity increases from 20 m/s to 40 m/s. Increasing the hot inlet diameter from 2 cm to 4 cm improves temperature distribution, raising the outlet temperature from 325.95 K to 329.797 K. The introduction of dual hot inlets further enhances the temperature to 329.797 K. Comparative analysis of turbulence models (k-ω and k-ε) indicates that the k-ω model provides more uniform temperature distribution. Moreover, variations in flow rates show that higher flow rates in the main pipe led to an outlet temperature of 312 K, while higher flow rates in the branch pipe reduced the outlet temperature to 305 K. This research offers critical insights for optimizing T-junction designs, improving thermal mixing, and enhancing heat transfer in industrial applications.

References

A. M. S. Chapuliot, C. Gourdin, T. Payen, J.P. Magnaud, “Hydro-thermal-mechanical analysis of thermal fatigue in a mixing tee,” Nucl. Eng. Des., vol. 235, no. 5, pp. 575–596, 2005, doi: https://doi.org/10.1016/j.nucengdes.2004.09.011.

J. T. Adeosun and A. Lawal, “Numerical and experimental studies of mixing characteristics in a T-junction microchannel using residence-time distribution,” Chem. Eng. Sci., vol. 64, no. 10, pp. 2422–2432, 2009, doi: https://doi.org/10.1016/j.ces.2009.02.013.

H. D. Zughbi, Z. H. Khokhar, and R. N. Sharma, “Mixing in pipelines with side and opposed tees,” Ind. Eng. Chem. Res., vol. 42, no. 21, pp. 5333–5344, Oct. 2003, doi: 10.1021/IE0209935;PAGEGROUP:STRING:PUBLICATION.

K. O. A. Ait Msaad, M. Mahdaoui, T. Kousksou, A. Allouhi, T. El Rhafiki, A. Jamil, “Numerical simulation of thermal chaotic mixing in multiple rods rotating mixer,” Case Stud. Therm. Eng., vol. 10, pp. 388–398, 2017, doi: https://doi.org/10.1016/j.csite.2017.09.005.

Q. Cao, D. Lu, and J. Lv, “Numerical investigation on temperature fluctuation of the parallel triple-jet,” Nucl. Eng. Des., vol. 249, pp. 82–89, 2012, doi: https://doi.org/10.1016/j.nucengdes.2011.07.018.

S. M. Hosseini, K. Yuki, and H. Hashizume, “Classification of turbulent jets in a T-junction area with a 90-deg bend upstream,” Int. J. Heat Mass Transf., vol. 51, no. 9–10, pp. 2444–2454, 2008, doi: https://doi.org/10.1016/j.ijheatmasstransfer.2007.08.024.

H. L. T. Lu, P.X. Jiang, Z.J. Guo, Y.W. Zhang, “Large-eddy simulations (LES) of temperature fluctuations in a mixing tee with/without a porous medium,” Int. J. Heat Mass Transf., vol. 53, no. 21–22, pp. 4458–4466, 2010, doi: https://www.sciencedirect.com/science/article/abs/pii/S0017931010003650?via%3Dihub.

R. I. Damora Rhakasywi, Harinaldi, Engkos A. Kosasih, “Computational and Experimental Study of Heat Transfer on the heat sink with an impinging synthetic jet under Various Excitation Wave,” Case Stud. Therm. Eng., vol. 26, p. 101106, 2021, doi: https://doi.org/10.1016/j.csite.2021.101106.

L.-W. Hu and M. S. Kazimi, “LES benchmark study of high cycle temperature fluctuations caused by thermal striping in a mixing tee,” Int. J. Heat Fluid Flow, vol. 27, no. 1, pp. 54–64, 2006, doi: https://doi.org/10.1016/j.ijheatfluidflow.2005.08.001.

Q. W. Kexin Huang, Bo Su, Tong Li, Hanbing Ke, Mei Lin, “Numerical simulation of the mixing behaviour of hot and cold fluids in the rectangular T-junction with/without an impeller,” Appl. Therm. Eng., vol. 204, p. 117942, 2022, doi: https://doi.org/10.1016/j.applthermaleng.2021.117942.

Y. M. F. C.H. Lin, “Investigating thermal mixing and reverse flow characteristics in a T-junction using CFD methodology,” Appl. Therm. Eng., vol. 102, pp. 733–741, 2016, doi: https://doi.org/10.1016/j.applthermaleng.2016.03.124.

C. S. Yu Shao, Y. Jeffrey Yang, Lijie Jiang, Tingchao Yu, “Experimental testing and modeling analysis of solute mixing at water distribution pipe junctions,” Water Res., vol. 56, pp. 133–147, 2014, doi: https://doi.org/10.1016/j.watres.2014.02.053.

Z. Mi, R. Kulenovic, and E. Laurien, “T-junction experiment with high temperature and high pressure to investigate flow rate influence on mixing characteristics,” Int. J. Heat Fluid Flow, vol. 71, pp. 451–459, 2018, doi: https://doi.org/10.1016/j.ijheatfluidflow.2018.05.004.

A. Sakowitz, M. Mihaescu, and L. Fuchs, “Effects of velocity ratio and inflow pulsations on the flow in a T-junction by Large Eddy Simulation,” Comput. Fluids, vol. 88, pp. 374–385, 2013, doi: https://doi.org/10.1016/j.compfluid.2013.10.001.

S. J. Wang and A.S. Mujumdar, “Flow and mixing characteristics of multiple and multi-set opposing jets,” Chem. Eng. Process. Process Intensif., vol. 46, no. 8, pp. 703–712, 2007, doi: https://doi.org/10.1016/j.cep.2006.09.006.

C. Evrim and E. Laurien, “Numerical study of thermal mixing mechanisms in T-junctions,” Appl. Therm. Eng., vol. 183, no. 1, p. 116155, 2021, doi: https://doi.org/10.1016/j.applthermaleng.2020.116155.

A. Maurya, N. Tiwari, and R. P. Chhabra, “Thermal Mixing of Impinging Laminar Streams of Shear-Thinning Fluids,” Heat Transf. Eng., vol. 41, no. 18, pp. 1576–1595, Oct. 2020, doi: 10.1080/01457632.2019.1661667.

F. M. Th. Frank, C. Lifante, H.-M. Prasser, “Simulation of turbulent and thermal mixing in T-junctions using URANS and scale-resolving turbulence models in ANSYS CFX,” Nucl. Eng. Des., vol. 240, no. 9, pp. 2313–2328, 2010, doi: https://doi.org/10.1016/j.nucengdes.2009.11.008.

J. Dahlberg, M ; Chapuliot, D ; Bretherton, I ; Faidy, C ; Church, M ; Chapuliot, S ; Wilke, U ; Taylor, N ; Solin, “Development of a European procedure for assessment of high cycle thermal fatigue in light water reactors: Final report of the NESC-thermal fatigue project,” Publ. Off. Eur. Union, 2007, [Online]. Available: https://op.europa.eu/en/publication-detail/-/publication/f74e08dd-b6f1-45ec-b985-a378067f16af

C. Brücker, “Study of the three-dimensional flow in a T-junction using a dual-scanning method for three-dimensional scanning-particle-image velocimetry (3-D SPIV),” Exp. Therm. Fluid Sci., vol. 14, no. 1, pp. 35–44, 1997, doi: https://doi.org/10.1016/S0894-1777(96)00110-0.

K. H. H. Kamide, M. Igarashi, S. Kawashima, N. Kimura, “Study on mixing behavior in a tee piping and numerical analyses for evaluation of thermal striping,” Nucl. Eng. Des., vol. 239, no. 1, pp. 58–67, 2009, doi: https://doi.org/10.1016/j.nucengdes.2008.09.005.

A. E. A. and S. A. K. Aleksandr V. Obabko, Paul F. Fischer, Timothy J. Tautges, Vasily M. Goloviznin, Mikhail A. Zaytsev, Vladimir V. Chudanov, Valeriy A. Pervichko, “Large Eddy Simulation of Thermo-Hydraulic Mixing in a T-Junction,” Nucl. React. Therm. Hydraul. Other Appl., 2013, doi: 10.5772/53143.

A. Blahoianu and A. Huerta, “OECD/NEA Activities to Support Long Term Operation,” J. Disaster Res., vol. 5, no. 6, pp. 707–711, Dec. 2010, doi: 10.20965/JDR.2010.P0707.

Thomas Höhne, “Scale resolved simulations of the OECD/NEA–Vattenfall T-junction benchmark,” Nucl. Eng. Des., vol. 269, pp. 149–154, 2014, doi: https://doi.org/10.1016/j.nucengdes.2013.08.021.

H. Ayhan and C. N. Sökmen, “CFD modeling of thermal mixing in a T-junction geometry using LES model,” Nucl. Eng. Des., vol. 253, pp. 183–191, 2012, doi: https://doi.org/10.1016/j.nucengdes.2012.08.010.

K. A. B.L. Smith, J.H. Mahaffy, “A CFD benchmarking exercise based on flow mixing in a T-junction,” Nucl. Eng. Des., vol. 264, pp. 80–88, 2013, doi: https://doi.org/10.1016/j.nucengdes.2013.02.030.

R. D. Lazarov, I. D. Mishev, and P. S. Vassilevski, “Finite volume methods for convection-diffusion problems,” SIAM J. Numer. Anal., vol. 33, no. 1, pp. 31–55, Jul. 1996, doi: 10.1137/0733003;WGROUP:STRING:PUBLICATION.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 50sea

This work is licensed under a Creative Commons Attribution 4.0 International License.