Eco-Friendly Nano Catalyst Preparation for Biodiesel Production from Melia azedarach Seeds: A Step Toward Climate Mitigation

Keywords:

Biodiesel, Melia Azedarach, Climate Change, TransesterificationAbstract

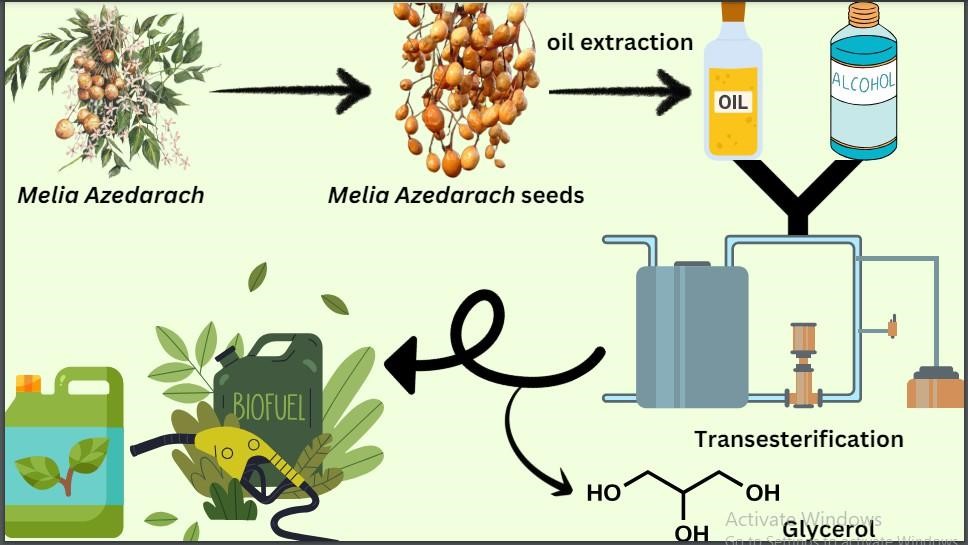

Biodiesel is a renewable and sustainable alternative to fossil fuels, offering a cleaner source of energy with significantly reduced greenhouse gas emissions. This study explores the production of biodiesel from non-edible Melia azedarach seed oil using green synthesis through TiO₂ nanocatalysts. Oil was extracted using n-hexane, and transesterification was performed under different conditions of the molar ratio of oil-to-methanol (1:3, 1:6, 1:9, 1:12, and 1:15), temperatures (70, 80, 90, 120, and 140 °C), concentration of TiO₂ catalyst (0.3, 0.5, 0.7, 0.9, and 1 g), and reaction times (1, 2, 3, 4, and 5 hours). Maximum biodiesel yield (93%) was achieved when the molar ratio was 1:12, the temperature was 80 °C, the weight of the TiO₂ catalyst was 0.7 g, and the reaction time was 3 hours. Fourier Transform Infrared Spectroscopy, X-ray Diffraction (XRD), and Scanning Electron Microscopy (SEM) were used to characterize the TiO₂ nanocatalyst and verified its catalytic activity and structure. The FTIR characterization of the produced biodiesel verified the presence of methyl esters. The use of non-edible feedstock like Melia azedarach is eco-friendly since it is not in food-vs-fuel competition and can be grown on marginal lands. Secondly, the method combats global climate change by minimizing the use of fossil fuels and carbon emissions. Through this research, it is proven that biodiesel synthesis using non-edible feedstock (Melia azedarach seed oil) is a sustainable method of climate-resilient large-scale biodiesel production in accordance with renewable energy and climate resilience criteria.

References

K. Kanwal et al., “Implication of scanning electron microscopy and light microscopy for oil content determination and seed morphology of Verbenaceae,” Microsc. Res. Tech., vol. 85, no. 2, pp. 789–798, Feb. 2022, doi: 10.1002/JEMT.23950;WEBSITE:WEBSITE:ANALYTICALSCIENCEJOURNALS;WGROUP:STRING:PUBLICATION.

P. L. S. Mamoona Munir, Mushtaq Ahmad, Muhammad Mubashir, Saira Asif, Amir Waseem, Ahmad Mukhtar, Sidra Saqib, Heli Siti Halimatul Munawaroh, Man Kee Lam, Kuan Shiong Khoo, Awais Bokhari d, “A practical approach for synthesis of biodiesel via non-edible seeds oils using trimetallic based montmorillonite nano-catalyst,” Bioresour. Technol., vol. 328, p. 124859, 2021, doi: https://doi.org/10.1016/j.biortech.2021.124859.

Sylvia Adipah, “Introduction of Biodiesel as a Sustainable Resource,” J. Environ. Sci. Public Heal., vol. 3, no. 1, 2018, [Online]. Available: https://www.fortunejournals.com/articles/introduction-of-biodiesel-as-a-sustainable-resource.html

R. Alrefai, A. M. Alrefai, J. Stokes, and K. Y. Benyounis, “The Production of Biogas, Biodiesel as High-Value Bio-Based Product and Multiple Bio-Products Through an Integration Approach of the Anaerobic Digestion and Fermentation Processes,” Encycl. Renew. Sustain. Mater., vol. 1, pp. 686–694, 2020, doi: https://doi.org/10.1016/B978-0-12-803581-8.11659-5.

O. S. I. F. A.A. Ayoola, “Biodiesel Fuel Production Processes: A Short Review,” IOP Conf. Ser. Mater. Sci. Eng., vol. 1107, no. 1, p. 4, 2021, doi: 10.1088/1757-899X/1107/1/012151.

M. A. H. Shafaq Nisar, “Trends in Widely Used Catalysts for Fatty Acid Methyl Esters (FAME) Production: A Review,” Catalysts, vol. 11, no. 9, p. 1085, 2021, doi: https://doi.org/10.3390/catal11091085.

W. Z. Lijian Leng, Pei Han, Xingzhong Yuan, Jun Li, “Biodiesel microemulsion upgrading and thermogravimetric study of bio-oil produced by liquefaction of different sludges,” Energy, vol. 153, pp. 1061–1072, 2018, doi: https://doi.org/10.1016/j.energy.2018.04.087.

J. M. M. Gebremariam, Shemelis Nigatu, “Biodiesel production technologies: Review,” AIMS Energy, vol. 5, no. 3, pp. 425–457, 2017, doi: 10.3934/energy.2017.3.425.

Z. Kaczor, Z. Kaczor, and S. Werle, “Modelling approaches to waste biomass pyrolysis: a review,” Renew. Energy, vol. 159, pp. 427–443, 2020, doi: https://doi.org/10.1016/j.renene.2020.05.110.

A. K. C. Avinash P. Ingle, “Advances in Nanocatalysts Mediated Biodiesel Production: A Critical Appraisal,” Symmetry (Basel)., vol. 12, no. 2, p. 256, 2020, doi: https://doi.org/10.3390/sym12020256.

H. C. O. I. M. Rizwanul Fattah, “State of the Art of Catalysts for Biodiesel Production,” Front. Energy Res, vol. 8, 2020, doi: https://doi.org/10.3389/fenrg.2020.00101.

H. C. O. A.S. Silitonga, A.H. Shamsuddin, T.M.I. Mahlia, Jassinne Milano, F. Kusumo, Joko Siswantoro, S. Dharma, A.H. Sebayang, H.H. Masjuki, “Biodiesel synthesis from Ceiba pentandra oil by microwave irradiation-assisted transesterification: ELM modeling and optimization,” Renew. Energy, vol. 146, pp. 1278–1291, 2020, doi: https://doi.org/10.1016/j.renene.2019.07.065.

V. Nisar, S., Hanif, M. A., Rashid, U., Hanif, A., Akhtar, M. N., & Ngamcharussrivichai, “Optimization and Kinetic Modeling of Biodiesel Production,” Encycl. Renew. Sustain. Mater., 2018, doi: 10.1016/B978-0-12-803581-8.10578-8.

E. E. Garcia-Silvera, I. Melendez-Mogollon, A. Pérez-Arias, and Y. A. de la Rosa, “Enzymatic Biodiesel Production: Challenges and Opportunities,” Green Energy Technol., pp. 19–37, 2023, doi: 10.1007/978-3-031-26813-7_2.

A. M. D. C. Bernardo Dias Ribeiro, “Production and Use of Lipases in Bioenergy: A Review from the Feedstocks to Biodiesel Production,” Enzyme Res., 2011, [Online]. Available: https://pmc.ncbi.nlm.nih.gov/articles/PMC3137985/

M. Elkelawy et al., “WCO biodiesel production by heterogeneous catalyst and using cadmium (II)-based supramolecular coordination polymer additives to improve diesel/biodiesel fueled engine performance and emissions,” J. Therm. Anal. Calorim., vol. 147, no. 11, pp. 6375–6391, Jun. 2022, doi: 10.1007/S10973-021-10920-1/METRICS.

V. Mittal and U. K. Ghosh, “Comparative analysis of two different nanocatalysts for producing biodiesel from microalgae,” Mater. Today Procedding, vol. 63, pp. 515–519, 2022, doi: https://doi.org/10.1016/j.matpr.2022.03.652.

V. A. Hwai Chyuan Ong, Wei-Hsin Chen, Abid Farooq, Yong Yang Gan, Keat Teong Lee, “Catalytic thermochemical conversion of biomass for biofuel production: A comprehensive review,” Renew. Sustain. Energy Rev., vol. 113, p. 109266, 2019, doi: https://doi.org/10.1016/j.rser.2019.109266.

S. Chandren and R. Rusli, “Biosynthesis of TiO2 Nanoparticles and Their Application as Catalyst in Biodiesel Production,” Green Nano Solut. Bioenergy Prod. Enhanc. , pp. 127–168, 2022, doi: 10.1007/978-981-16-9356-4_6.

H. K. E. L. K.V. Yatish, H.S. Lalithamba, R. Suresh, “Ochrocarpus longifolius assisted green synthesis of CaTiO3 nanoparticle for biodiesel production and its kinetic study,” Renew. Energy, vol. 147, no. 1, pp. 310–321, 2020, doi: https://doi.org/10.1016/j.renene.2019.08.139.

Y. Z. Jinshuai Ba, Guangtao Wei, Zhongmin Li, Linye Zhang, Ruinan Pei, Jiajun Xu, “Castor oil transesterification catalyzed by a new red mud based LiAlO2-LiFeO2 composite,” Energy Convers. Manag., vol. 254, p. 115214, 2022, doi: https://doi.org/10.1016/j.enconman.2022.115214.

B. S. Basir Maleki, Hossein Esmaeili, Mohsen Mansouri, Dipesh Kumar, “Enhanced conversion of dairy waste oil to biodiesel via novel and highly reactive UiO-66-NH2/ZnO/TiO2 nano-catalyst: Optimization, kinetic, thermodynamic and diesel engine studies,” Fuel, vol. 339, p. 126901, 2023, doi: https://doi.org/10.1016/j.fuel.2022.126901.

Hossein Esmaeili, “A critical review on the economic aspects and life cycle assessment of biodiesel production using heterogeneous nanocatalysts,” Fuel Process. Technol., vol. 230, p. 107224, 2022, doi: https://doi.org/10.1016/j.fuproc.2022.107224.

P. C. B. Manas Ranjan Senapati, “Chapter 3 - Novel extraction conditions for phytochemicals,” Recent Front. Phytochem., pp. 27–61, 2023, doi: https://doi.org/10.1016/B978-0-443-19143-5.00019-0.

M. A. M. Maryam Tanveer Akhtar, Mushtaq Ahmad, Maliha Asma, Mamoona Munir, Muhammad Zafar, Shazia Sultana, “Efficient Production of Wild and Non-Edible Brassica juncea (L.) Czern. Seed Oil into High-Quality Biodiesel via Novel, Green and Recyclable NiSO4 Nano-Catalyst,” Sustainability, vol. 14, no. 6, p. 10188, 2022, doi: https://doi.org/10.3390/su141610188.

M. A. Maryam Tanveer Akhtar, “Comparative Study of Liquid Biodiesel From Sterculia foetida (Bottle Tree) Using CuO-CeO2 and Fe2O3 Nano Catalysts,” Front. Energy Res, vol. 7, 2019, doi: https://doi.org/10.3389/fenrg.2019.00004.

S. H. F.I. Gómez-Castro, C. Gutiérrez-Antonio, A.G. Romero-Izquierdo, M.M. May-Vázquez, “Intensified technologies for the production of triglyceride-based biofuels: Current status and future trends,” Renew. Sustain. Energy Rev., vol. 184, p. 113580, 2023, doi: https://doi.org/10.1016/j.rser.2023.113580.

E. Emmanouilidou, A. Lazaridou, S. Mitkidou, and N. C. Kokkinos, “A comparative study on biodiesel production from edible and non-edible biomasses,” J. Mol. Struct., vol. 1306, p. 137870, 2024, doi: https://doi.org/10.1016/j.molstruc.2024.137870.

M. S. Rahman, M. M., Chowdhury, M. A., & Hossain, “Effect of free fatty acid on biodiesel yield from various feedstocks,” Fuel, vol. 338, p. 127580, 2023, doi: https://doi.org/10.1016/j.fuel.2023.127580.

X. Chen, Y., Wang, H., Liu, Z., & Li, “Ultrafine TiO₂ nanocatalysts for high-yield biodiesel production,” Catal. Today, vol. 412, pp. 123–130, 2023.

P. J. Vivek Patidar, “Green Synthesis of TiO2 Nanoparticle Using Moringa Oleifera Leaf Extract,” Int. Res. J. Eng. Technol., vol. 4, no. 3, 2017, [Online]. Available: https://www.irjet.net/archives/V4/i3/IRJET-V4I3134.pdf

W. Zhou, M., Liu, L., & Zhao, “Bio-assisted synthesis of metal oxide catalysts: Surface chemistry and biofunctionality,” J. Environ. Chem. Eng., vol. 9, no. 6, p. 106434, 2021.

M. T. Nguyen, H. V., Tran, T. D., & Le, “Effect of catalyst loading on transesterification using ZnO@biochar nanocatalysts,” Biomass Convers. Biorefinery, vol. 13, pp. 981–990, 2023.

A. Singh, R., Verma, P., & Shukla, “Transesterification optimization using novel heterogeneous catalysts,” Energy Reports, vol. 7, pp. 1400–1408, 2021, doi: https://doi.org/10.1016/j.egyr.2021.02.043.

J. O. Oladipo, A. A., Afolabi, A. S., & Ojediran, “Thermal effects on TiO₂ nanocatalysts during biodiesel synthesis,” Sustain. Energy Technol. Assessments, vol. 51, 2022, doi: https://doi.org/10.1016/j.seta.2022.101975.

A. Yadav, A., Patel, R., & Das, “Kinetic modeling and energy efficiency in biodiesel production,” Bioresour. Technol. Reports, vol. 22, p. 101056, 2024.

M. Saad, B. Siyo, and H. Alrakkad, “Preparation and characterization of biodiesel from waste cooking oils using heterogeneous Catalyst(Cat.TS-7) based on natural zeolite,” Heliyon, vol. 9, no. 6, p. e15836, 2023, doi: https://doi.org/10.1016/j.heliyon.2023.e15836.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 50sea

This work is licensed under a Creative Commons Attribution 4.0 International License.