Hybrid Integration Model in Industry 4.0 for Lean Management (HIM)

Keywords:

System Integration, Industry 4.0, Lean Management, Inbound and Outbound Integration, ERP, General Ledger, GDSAbstract

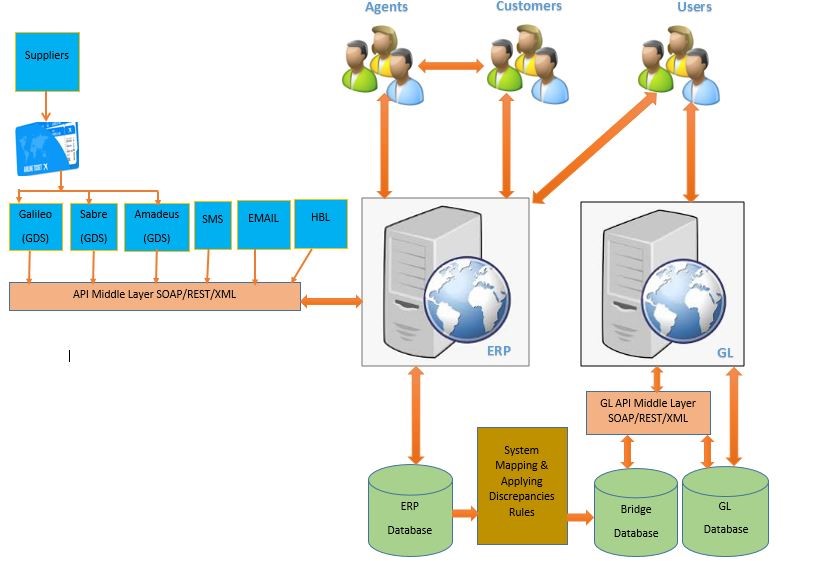

In many large organizations, there is an Enterprise Resource Planning (ERP) system that needs to be integrated with a third-party system to provide real-time services to their customers. To achieve this, these organizations’(ERP) systems should have inbound (IB) and outbound (OB) integration capability through APIs. In this paper, we have proposed and implemented a Hybrid Integration Model (HIM) in Industry 4.0 for Lean Management. This research was implemented in an Airline Travel Company (ATC) in which an In-house ERP system is real-time-integrated (In-bound) with Global Distribution System (GDS) through API’s i-e, soap &rest-based web services for online ticketing as well other Miscellaneous facilities i-e (Auto SMS Email) using Horizontal Integration Model in Industry 4.0 and also integrated (Outbound) with 3rd party General Ledger (GL) system. Integrating an ERP system with GL is an automated business process that requires implementing API’s and developing automatic routines to move the data between ERP & GL Systems as per user requirements. Our proposed model is fully automated where no human intervention is involved while transferring data from ERP to GL and following all standards recommended by industry 4.0 for Lean Management.

References

What is System Integration, and how do you do it? [online] FOLIO3 MICROSOFT DYNAMICS PARTNER Available at: https://dynamics.folio3.com/blog/systemintegration/ [Accessed 10 OCT. 2020].

Advantages of System Integration [online] Fida-E Zaheer Available at: https://www.syncoria.com/blog/advantages-of-system-integration/?cv=1 [Accessed 10 OCT. 2020].

5 benefits of systems integration [online] Available at: https://headchannel.co.uk/5- benefits-of-system-integration-321 [Accessed 10 OCT. 2020].

Wang, S., Wan, J., Li, D., & Zhang, C. (2016). Implementing smart factory of industrie4.0:

an outlook. International journal of distributed sensor networks, 12(1), 3159805.

Foidl, H., Felderer, M. (2015, November). Research challenges of industry 4.0 for quality management. In International Conference on Enterprise Resource Planning Systems (pp. 121-137). Springer, Cham.

Sindi, S., & Roe, M. (2017). The evolution of supply chains and logistics. In Strategic supply chain management (pp. 7-25). Palgrave Macmillan, Cham.

Weyer, S., Schmitt, M., Ohmer, M., &Gorecky, D. (2015). Towards Industry 4.0- Standardization as the crucial challenge for highly modular, multi-vendor production

systems. Ifac-Papersonline, 48(3), 579-584.

Stock, T., Seliger, G. (2016). Opportunities of sustainable manufacturing in industry 4.0. Procedia Cirp, 40, 536-541.

Sony, M. (2018). Industry 4.0 and lean management: a proposed integration model and research propositions. Production & Manufacturing Research, 6(1), 416-432.

Huma Pervez, Anila Usman; An Innovative B2B ERP Model for Airline Travel Industry; North American Academic Research, 3(9) 127-155, 2020, https://doi.org/10.5281/zenodo.4047195

General ledger definitionMarch 01, 2022 [Online] https://www.accountingtools.com/articles/general-ledger [Accessed 29 Apr. 2022]

Important IT Development l relating to Industry 4.0 in Pakistan [Online] https://cttcnet.typepad.com/cttc_technology_blog/2019/04/important-it-develelopment-in-april-relating-to-industry-40-in-pakistan.html [Accessed 01 May. 2022]

Bousdekis, A., Lepenioti, K., Apostolou, D., &Mentzas, G. (2021). A review of data-driven decision-making methods for industry 4.0 maintenance applications. Electronics, 10(7), 828.

M. Breque, L. De Nul, A. Petridis Industry 5.0: towards a sustainable, human-centric and resilient European industryEuropean Commission, Directorate-General for

Research and Innovation, Luxembourg, LU (2021).

Xu, X., Lu, Y., Vogel-Heuser, B., & Wang, L. (2021). Industry 4.0 and Industry 5.0—Inception, conception and perception. Journal of Manufacturing Systems, 61, 530-535.

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 50SEA

This work is licensed under a Creative Commons Attribution 4.0 International License.