Predictive Maintenance Using Deep Learning: Enhancing Reliability and Reducing Electrical System Downtime

DOI:

https://doi.org/10.33411/ijist/20246311201136Keywords:

Predictive maintenance (PdM), Deep Learning, Downtime Minimization, Neural Networks, Failure PredictionAbstract

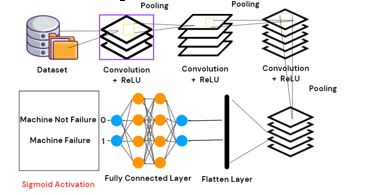

Predictive Maintenance (PM) is crucial for enhancing the reliability of electrical systems and minimizing unscheduled outages. However, the conventional methodology lacks the ability to address the escalating and diverse problems of the modern complex environment. The current study provides an alternative approach to carrying out the predictive maintenance activity based on the use of deep learning models that enhance conventional procedures. For the given analysis, we used an artificial data set consisting of 10,000 samples and 14 variables, such as air temperature, process temperature, flipping rate, and tool wear level. We conducted a self-assessment using the specified models to confirm their effectiveness in predicting various failure modes and forms, such as tool wear and heat dissipation conking. This research demonstrated that deep learning models, specifically LSTMs, outperform the established statistical methods in predicting equipment failures. LSTMs provided high accuracy and predicted the failing system before it happened. Furthermore, integrating deep learning with the statistical method that is normally used for anomaly detection improves the model's stability and reliability. The evaluation's findings emphasize the potential of deep learning algorithms for expanding the range of PM applications to achieve better and faster failure predictions. The beneficial thing about this approach is that it presents a means for addressing the inherent problems of large electrical systems’ predictive maintenance that are beyond the scope of traditional practice.

References

T. Zhu, Y. Ran, X. Zhou, and Y. Wen, “A Survey of Predictive Maintenance: Systems, Purposes and Approaches,” Dec. 2019, Accessed: Aug. 12, 2024. [Online]. Available: https://arxiv.org/abs/1912.07383v2

“(PDF) Intelligent Maintenance Systems and Predictive Manufacturing.” Accessed: Aug. 12, 2024. [Online]. Available: https://www.researchgate.net/publication/343121327_Intelligent_Maintenance_Systems_and_Predictive_Manufacturing

O. Asif, S. A. L. I. Haider, S. R. Naqvi, J. F. W. Zaki, K. S. Kwak, and S. M. R. Islam, “A Deep Learning Model for Remaining Useful Life Prediction of Aircraft Turbofan Engine on C-MAPSS Dataset,” IEEE Access, vol. 10, pp. 95425–95440, 2022, doi: 10.1109/ACCESS.2022.3203406.

H. Liu, J. Zhou, Y. Zheng, W. Jiang, and Y. Zhang, “Fault diagnosis of rolling bearings with recurrent neural network-based autoencoders,” ISA Trans., vol. 77, pp. 167–178, Jun. 2018, doi: 10.1016/J.ISATRA.2018.04.005.

T. Fawcett, “An introduction to ROC analysis,” Pattern Recognit. Lett., vol. 27, no. 8, pp. 861–874, Jun. 2006, doi: 10.1016/J.PATREC.2005.10.010.

D. Lee and R. Pan, “Predictive maintenance of complex system with multi-level reliability structure,” Int. J. Prod. Res., vol. 55, no. 16, pp. 4785–4801, Aug. 2017, doi: 10.1080/00207543.2017.1299947.

M. J. Scott, W. J. C. Verhagen, M. T. Bieber, and P. Marzocca, “A Systematic Literature Review of Predictive Maintenance for Defence Fixed-Wing Aircraft Sustainment and Operations,” Sensors 2022, Vol. 22, Page 7070, vol. 22, no. 18, p. 7070, Sep. 2022, doi: 10.3390/S22187070.

M. Sisode and M. Devare, “A Review on Machine Learning Techniques for Predictive Maintenance in Industry 4.0,” pp. 774–783, 2023, doi: 10.2991/978-94-6463-136-4_67.

S. Kaparthi and D. Bumblauskas, “Designing predictive maintenance systems using decision tree-based machine learning techniques,” Int. J. Qual. Reliab. Manag., vol. 37, no. 4, pp. 659–686, Mar. 2020, doi: 10.1108/IJQRM-04-2019-0131/FULL/XML.

Y. H. Hung, “Improved Ensemble-Learning Algorithm for Predictive Maintenance in the Manufacturing Process,” Appl. Sci. 2021, Vol. 11, Page 6832, vol. 11, no. 15, p. 6832, Jul. 2021, doi: 10.3390/APP11156832.

M. Sohaib, S. Mushtaq, and J. Uddin, “Deep Learning for Data-Driven Predictive Maintenance,” Intell. Syst. Ref. Libr., vol. 207, pp. 71–95, 2021, doi: 10.1007/978-3-030-75490-7_3.

D. Bruneo and F. De Vita, “On the use of LSTM networks for predictive maintenance in smart industries,” Proc. - 2019 IEEE Int. Conf. Smart Comput. SMARTCOMP 2019, pp. 241–248, Jun. 2019, doi: 10.1109/SMARTCOMP.2019.00059.

A. L. Alfeo, M. G. C. A. Cimino, G. Manco, E. Ritacco, and G. Vaglini, “Using an autoencoder in the design of an anomaly detector for smart manufacturing,” Pattern Recognit. Lett., vol. 136, pp. 272–278, Aug. 2020, doi: 10.1016/J.PATREC.2020.06.008.

“Advanced Artificial Intelligence Techniques for Real-Time Predictive Maintenance in Industrial IoT Systems: A Comprehensive Analysis and Framework | Journal of AI-Assisted Scientific Discovery.” Accessed: Aug. 12, 2024. [Online]. Available: https://scienceacadpress.com/index.php/jaasd/article/view/83

S. Cho et al., “A hybrid machine learning approach for predictive maintenance in smart factories of the future,” IFIP Adv. Inf. Commun. Technol., vol. 536, pp. 311–317, 2018, doi: 10.1007/978-3-319-99707-0_39.

S. Sridhar and S. Sanagavarapu, “Handling Data Imbalance in Predictive Maintenance for Machines using SMOTE-based Oversampling,” Proc. - 2021 IEEE 13th Int. Conf. Comput. Intell. Commun. Networks, CICN 2021, pp. 44–49, Sep. 2021, doi: 10.1109/CICN51697.2021.9574668.

R. Naren and J. Subhashini, “Comparison of deep learning models for predictive maintenance,” IOP Conf. Ser. Mater. Sci. Eng., vol. 912, no. 2, Sep. 2020, doi: 10.1088/1757-899X/912/2/022029.

H. Hesabi, M. Nourelfath, and A. Hajji, “A deep learning predictive model for selective maintenance optimization,” Reliab. Eng. Syst. Saf., vol. 219, p. 108191, Mar. 2022, doi: 10.1016/J.RESS.2021.108191.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 50SEA

This work is licensed under a Creative Commons Attribution 4.0 International License.