A Machine Learning Prediction of Mechanical Properties in Reinforcement Bars: A Data-Driven Approach

Keywords:

Machine Learning, Reinforcement Bars (Rebars), Data-Driven Approach, Chemical Composition, Quality ControlAbstract

Introduction/Importance of Study: This study addresses the pressing need for precise prediction of mechanical properties in steel reinforcement bars (rebars) through a data-driven approach utilizing machine learning techniques.

Novelty statement: Our research provides a solution to the challenge of predicting mechanical properties in rebars using advanced machine learning algorithms, filling a critical gap in existing methodologies.

Material and Method: Our study utilized a meticulously curated dataset comprising over 10,300 samples of diverse rebar types manufactured through industrial methods. We leveraged the latest PyCaret model to integrate machine learning algorithms, with a focus on training and rigorously testing linear regression models. Data preprocessing involved thorough cleaning using Python libraries such as Pandas and NumPy, supplemented by cross-validation techniques to ensure robust model generalization.

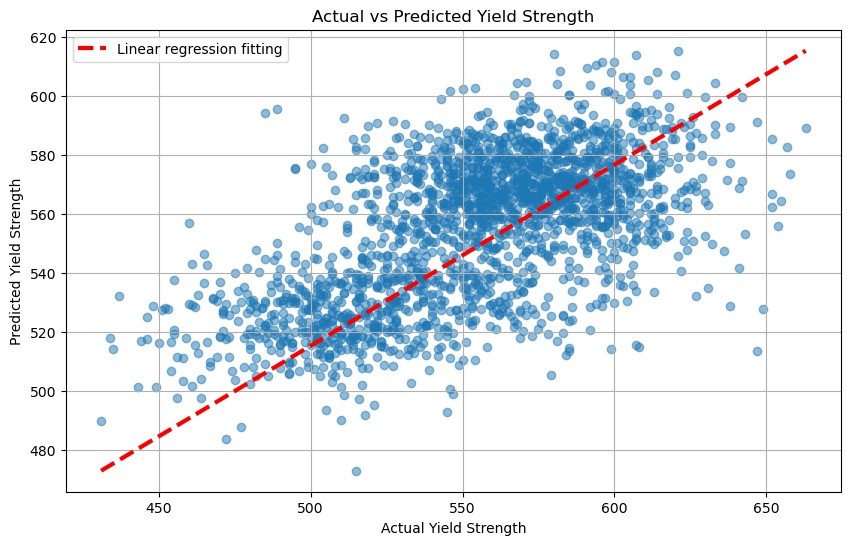

Result and Discussion: The core findings of our study revolve around the linear regression model algorithm trained within the machine learning framework, enabling precise determination of key mechanical properties including Yield Strength (YS) and ultimate Tensile Strength (UTS). Additionally, we explored the Ratio of UTS to YS (UTS/YS) as a critical mechanical property, incorporating essential input features such as weight percent of carbon (C), manganese (Mn), silicon (Si), carbon equivalent (Ceq), quenching parameters (Q), and diameter (d).

Concluding Remarks: Our research offers valuable insights into the application of machine learning for the precise prediction of mechanical properties in reinforcement bars, contributing to enhanced quality control and optimization in the steel manufacturing industry.

References

ASTM A615/A615M-12, “Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement,” Asm Int., 2012, doi: 10.1520/A0615.

British Standards Institution., “BS 4449:2005+A2:2009 : steel for the reinforcement of concrete : weldable reinforcing steel : bar, coil and decoiled product : specification,” vol. 3, p. 27, 2009.

F. Djavanroodi and A. Salman, “Variability of Mechanical Properties and Weight for Reinforcing Bar Produced in Saudi Arabia,” IOP Conf. Ser. Mater. Sci. Eng., vol. 230, no. 1, 2017, doi: 10.1088/1757-899X/230/1/012002.

Z. Wang, P. Liu, Y. Xiao, X. Cui, Z. Hu, and L. Chen, “A Data-Driven Approach for Process Optimization of Metallic Additive Manufacturing under Uncertainty,” J. Manuf. Sci. Eng. Trans. ASME, vol. 141, no. 8, 2019, doi: 10.1115/1.4043798.

M. Mohtasham Moein et al., “Predictive models for concrete properties using machine learning and deep learning approaches: A review,” J. Build. Eng., vol. 63, no. October 2022, 2023, doi: 10.1016/j.jobe.2022.105444.

Nwakamma Ninduwezuor-Ehiobu et al., “Tracing the Evolution of Ai and Machine Learning Applications in Advancing Materials Discovery and Production Processes,” Eng. Sci. Technol. J., vol. 4, no. 3, pp. 66–83, 2023, doi: 10.51594/estj.v4i3.552.

I. H. Sarker, “Machine Learning: Algorithms, Real-World Applications and Research Directions,” SN Comput. Sci., vol. 2, no. 3, 2021, doi: 10.1007/s42979-021-00592-x.

D. M. Jones, J. Watton, and K. J. Brown, “Comparison of hot rolled steel mechanical property prediction models using linear multiple regression, non-linear multiple regression and non-linear artificial neural networks,” Ironmak. Steelmak., vol. 32, no. 5, pp. 435–442, 2005, doi: 10.1179/174328105X48151.

T. M. H. Hope, “Linear regression,” in Machine Learning: Methods and Applications to Brain Disorders by Andrea Mechelli; Sandra Vieira, Elsevier Science, 2020, pp. 67–81.

D. Maulud and A. M. Abdulazeez, “A Review on Linear Regression Comprehensive in Machine Learning,” J. Appl. Sci. Technol. Trends, vol. 1, no. 4, pp. 140–147, Dec. 2020, doi: 10.38094/JASTT1457.

S. Jahanian and M. Mosleh, “Mathematical modeling of phase transformation of steel during quenching,” J. Mater. Eng. Perform., vol. 8, no. 1, pp. 75–82, 1999, doi: 10.1361/105994999770347197.

A. Stoll and P. Benner, “Machine learning for material characterization with an application for predicting mechanical properties,” GAMM Mitteilungen, vol. 44, no. 1, pp. 1–21, 2021, doi: 10.1002/gamm.202100003.

E. Ruiz, D. Ferreño, M. Cuartas, A. López, V. Arroyo, and F. Gutiérrez-Solana, “Machine learning algorithms for the prediction of the strength of steel rods: an example of data-driven manufacturing in steelmaking,” Int. J. Comput. Integr. Manuf., vol. 33, no. 9, pp. 880–894, 2020, doi: 10.1080/0951192X.2020.1803505.

R. H. F. Murta, F. D. Braga, P. P. N. Maia, O. B. F. Diógenes, and E. P. de Moura, “Mathematical modelling for predicting mechanical properties in rebar manufacturing,” Ironmak. Steelmak., vol. 48, no. 2, pp. 161–169, 2021, doi: 10.1080/03019233.2020.1749357.

M. V. Carneiro, T. T. Salis, G. M. Almeida, and A. P. Braga, “Prediction of Mechanical Properties of Steel Tubes Using a Machine Learning Approach,” J. Mater. Eng. Perform., vol. 30, no. 1, pp. 434–443, 2021, doi: 10.1007/s11665-020-05345-0.

A. Mukhopadhyay and A. Iqbal, “Prediction of mechanical property of steel strips using multivariate adaptive regression splines,” J. Appl. Stat., vol. 36, no. 1, pp. 1–9, 2009, doi: 10.1080/02664760802193252.

C. Singh Tumrate, S. Roy Chowdhury, and D. Mishra, “Development of Regression Model to Predicting Yield Strength for Different Steel Grades,” IOP Conf. Ser. Earth Environ. Sci., vol. 796, no. 1, 2021, doi: 10.1088/1755-1315/796/1/012033.

J. Krumeich, S. Jacobi, D. Werth, and P. Loos, “Big data analytics for predictive manufacturing control - A case study from process industry,” Proc. - 2014 IEEE Int. Congr. Big Data, BigData Congr. 2014, pp. 530–537, Sep. 2014, doi: 10.1109/BIGDATA.CONGRESS.2014.83.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 50sea

This work is licensed under a Creative Commons Attribution 4.0 International License.