Extraction of Bio-Oil from The Pyrolysis of Banana Tree Waste Using A Fixed-Bed Reactor

Keywords:

Biomass, Renewable Energy, Banana Tree Waste, Pyrolysis, Bio-oilAbstract

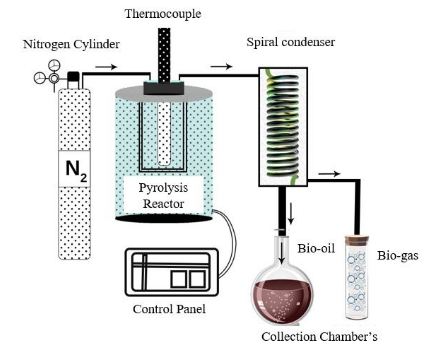

The rapid and ongoing depletion of fossil fuel reserves is driving up energy costs and harming the environment due to greenhouse gas emissions, leading to a global energy crisis. This situation highlights the urgent need to produce renewable fuel from biomass. This research focuses on extracting bio-oil from banana tree waste under different operating conditions. In this study, the pyrolysis process of banana tree waste was carried out in a fixed-bed reactor to maintain controlled conditions and prevent unwanted cracking. To optimize the process, the effects of temperature, particle size, and nitrogen flow rate on bio-oil yield were investigated. Experiments were conducted at temperatures ranging from 400 to 600 ℃, with feedstock particle sizes of 0.5 – 2.0 mm and nitrogen flow rates between 0.5 and 2 liters per minute. The optimal conditions for maximizing bio-oil yield were determined. Under these conditions, the maximum bio-oil yield of 32.13% was obtained at a temperature of 500 ℃, with a particle size of 1.2 – 2.0 mm and a nitrogen flow rate of 1 liter per minute. The results also demonstrate how temperature, particle size, and nitrogen flow affect the bio-oil yield during pyrolysis. The study concludes that banana tree waste can be efficiently converted into bio-oil through proper processing, contributing to sustainable energy production while minimizing environmental impact. The chemical composition of the bio-oil was analyzed using the GC-MS technique, which identified various compounds, including phenols, acids, and other chemical components.

References

A. I. Osman et al., “Cost, environmental impact, and resilience of renewable

energy under a changing climate: a review,” Environ. Chem. Lett., vol. 21, no. 2, pp. 741– 764, Apr. 2023, doi: 10.1007/s10311-022-01532-8.

J. S. Levine and J. S. Levine, “Biomass Burning and the Production of Greenhouse Gases,” 1994. [Online]. Available: https://www.researchgate.net/publication/24161310

S. Wangwongwatana, “Review of Existing Good Practices to Address Open Burning of Agricultural Residues.”

E. Menya et al., “A review of progress on torrefaction, pyrolysis and briquetting of banana plant wastes for biofuels,” 2024, Springer Science and Business Media Deutschland GmbH. doi: 10.1007/s13399-024-06204-x.

S. Alzate Acevedo, Á. J. Díaz Carrillo, E. Flórez-López, and C. D. Grande-Tovar, “Recovery of Banana Waste-Loss from Production and Processing: A Contribution to a Circular Economy,” Aug. 31, 2021, NLM (Medline). doi: 10.3390/molecules26175282.

K. Alper, K. Tekin, and S. Karagöz, “Pyrolysis of agricultural residues for bio-oil production,” Clean Technol. Environ. Policy, vol. 17, no. 1, pp. 211–223, Jan. 2015, doi: 10.1007/s10098-014-0778-8.

D. Gogoi, M. Kumar, and Y. G. Lakshmi, “A Comprehensive Review on ‘Pyrolysis’ for Energy Recovery,” Sep. 01, 2023, Springer. doi: 10.1007/s12155-023-10568-9.

C. Redondo-Gómez, M. R. Quesada, S. V. Astúa, J. P. M. Zamora, M. Lopretti, and J.

R. Vega-Baudrit, “Biorefinery of Biomass of Agro-Industrial Banana Waste to Obtain High-Value Biopolymers,” Sep. 01, 2020, MDPI AG. doi: 10.3390/molecules25173829.

N. Nuraini, N. B. Osman, and E. Astuti, “Bio-Oil Production Using Waste Biomass via Pyrolysis Process: Mini Review,” J. Bahan Alam Terbarukan, vol. 11, no. 1, pp. 37–49, Jun. 2022, doi: 10.15294/jbat.v11i1.37171.

N. Ayala Ruíz, ; Dionisio, and H. M. Romero, “Thermo-economic evaluation of a banana waste pyrolysis plant for biofuel production.”

A. N. Amenaghawon, C. L. Anyalewechi, C. O. Okieimen, and H. S. Kusuma, “Biomass pyrolysis technologies for value-added products: a state-of-the-art review,” Oct. 01, 2021, Springer Science and Business Media B.V. doi: 10.1007/s10668-021-01276-5.

M. Lee, H. Ko, and S. Oh, “Pyrolysis of Solid Recovered Fuel Using Fixed and Fluidized Bed Reactors,” Molecules, vol. 28, no. 23, Dec. 2023, doi: 10.3390/molecules28237815.

L. Maulinda et al., “The Influence of Pyrolysis Time and Temperature on the Composition and Properties of Bio-Oil Prepared from Tanjong Leaves (Mimusops elengi),” Sustain., vol. 15, no. 18, Sep. 2023, doi: 10.3390/su151813851.

R. S. Orozco et al., “Fruit residue to ethanol,” 2014.

R. M. Taib, N. Abdullah, and N. S. M. Aziz, “Bio-oil derived from banana pseudo-stem via fast pyrolysis process,” Biomass and Bioenergy, vol. 148, May 2021, doi: 10.1016/j.biombioe.2021.106034.

“Standard Method for Moisture Analysis of Particulate Wood Fuels 1.”

“Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels,” Aug. 15, 2013, ASTM International, West Conshohocken, PA. doi: 10.1520/E0872-82R13.

“Test Method for Ash in Wood,” Aug. 01, 2013, ASTM International, West Conshohocken, PA. doi: 10.1520/D1102-84R13.

“Designation: D 1106-96 (Reapproved 2007) Standard Test Method for Acid-Insoluble Lignin in Wood 1.” [Online]. Available: www.astm.org

D. Supramono, E. Kusrini, and H. Yuana, “Yield and Composition of Bio-oil from Co- Pyrolysis of Corn Cobs and Plastic Waste of HDPE in a Fixed Bed Reactor.”

M. Gonzalez et al., “Preparation and characterization of cellulose fibers from Meghatyrsus maximus: Applications in its chemical derivatives,” Carbohydr. Polym., vol. 296, p. 119918, Nov. 2022, doi: 10.1016/J.CARBPOL.2022.119918.

“ManuscriptCarbohydratePolymers (1).”

N. Sellin, D. R. Krohl, C. Marangoni, and O. Souza, “Oxidative fast pyrolysis of banana leaves in fluidized bed reactor,” Renew. Energy, vol. 96, pp. 56–64, Oct. 2016, doi: 10.1016/j.renene.2016.04.032.

B. Biswas, N. Pandey, Y. Bisht, R. Singh, J. Kumar, and T. Bhaskar, “Pyrolysis of agricultural biomass residues: Comparative study of corn cob, wheat straw, rice straw and rice husk,” Bioresour. Technol., vol. 237, pp. 57–63, 2017, doi: 10.1016/j.biortech.2017.02.046.

B. Biswas, N. Pandey, Y. Bisht, R. Singh, J. Kumar, and T. Bhaskar, “Pyrolysis of agricultural biomass residues: Comparative study of corn cob, wheat straw, rice straw and rice husk,” Bioresour. Technol., vol. 237, pp. 57–63, Aug. 2017, doi: 10.1016/J.BIORTECH.2017.02.046.

G. Bensidhom, A. Ben Hassen-Trabelsi, M. Sghairoun, K. Alper, and I. Trabelsi, “Pyrolysis of tunisian date palm residues for the production and characterization of bio- oil, bio-char and syngas,” in Advances in Science, Technology and Innovation, Springer Nature, 2018, pp. 1561–1563. doi: 10.1007/978-3-319-70548-4_453.

K. M. Isa, S. Daud, N. Hamidin, K. Ismail, S. A. Saad, and F. H. Kasim, “Thermogravimetric analysis and the optimisation of bio-oil yield from fixed-bed pyrolysis of rice husk using response surface methodology (RSM),” Ind. Crops Prod., vol. 33, no. 2, pp. 481–487, Mar. 2011, doi: 10.1016/J.INDCROP.2010.10.024.

S. Singh, A. Tagade, A. Verma, A. Sharma, S. P. Tekade, and A. N. Sawarkar, “Insights into kinetic and thermodynamic analyses of co-pyrolysis of wheat straw and plastic waste via thermogravimetric analysis,” Bioresour. Technol., vol. 356, p. 127332, Jul. 2022, doi: 10.1016/J.BIORTECH.2022.127332.

M. Landrat, M. T. Abawalo, K. Pikoń, and R. Turczyn, “Bio-Oil Derived from Teff Husk via Slow Pyrolysis Process in Fixed Bed Reactor and Its Characterization,” Energies, vol. 15, no. 24, Dec. 2022, doi: 10.3390/en15249605.

S. Das and V. V. Goud, “RSM-optimised slow pyrolysis of rice husk for bio-oil production and its upgradation,” Energy, vol. 225, p. 120161, Jun. 2021, doi: 10.1016/J.ENERGY.2021.120161.

A. S. Paul, N. L. Panwar, B. L. Salvi, S. Jain, and D. Sharma, “Experimental investigation on the production of bio-oil from wheat straw,” Energy Sources, Part A Recover. Util. Environ. Eff., vol. 46, no. 1, pp. 9777–9792, 2020, doi: 10.1080/15567036.2020.1779416.

G. Bensidhom et al., “Fast pyrolysis of date palm biomass using Py-GCMS,” J. Energy Inst., vol. 99, no. September, pp. 229–239, 2021, doi: 10.1016/j.joei.2021.09.012.

Y. Makkawi, Y. El Sayed, M. Salih, P. Nancarrow, S. Banks, and T. Bridgwater, “Fast pyrolysis of date palm (Phoenix dactylifera) waste in a bubbling fluidized bed reactor,” Renew. Energy, vol. 143, pp. 719–730, 2019, doi: 10.1016/j.renene.2019.05.028.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 50sea

This work is licensed under a Creative Commons Attribution 4.0 International License.