Optimization of Production Planning with Python’s SciPy: A Computational Study

Keywords:

Optimization, Linear Programming (LP), Python, Production Planning Problem, SciPyAbstract

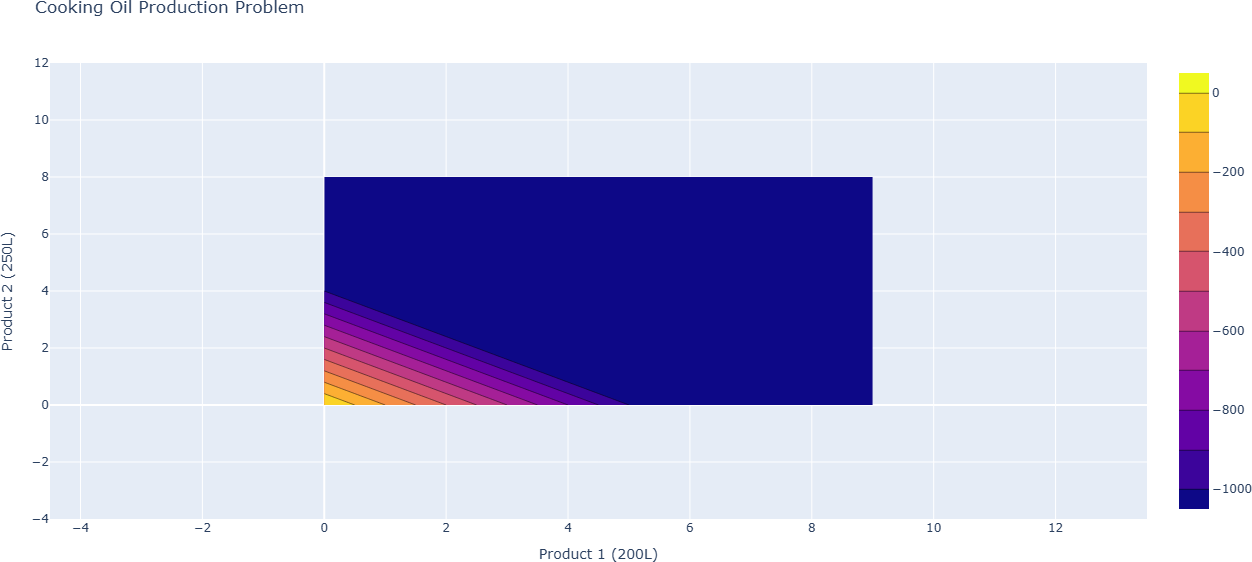

Production planning optimization is the act of effectively distributing limited resources, including labor, materials, and equipment, to achieve production targets while optimizing profit and reducing waste. This study analyzes how optimization methods can be applied to production planning models in the cooking oil sector, with a particular emphasis on how linear programming (LP) can be used to handle usable quality limitations to maximize gross profit. The goal of this study is to find the best values for decision variables across a variety of inventory-based production frameworks. It is important in a manufacturing zone where input bound must be weighed against consumer needs, such as the industry of cooking oil. In order to provide a computational method for determining the perfect production levels, the study establishes a linear programming (LP) model and solves it using Python’s SciPy package. This optimization method uses objective functions involving dense matrices and numerical equations to solve the production planning problem. In calculating output levels and profit margins, the numerical results show a significant convergence, rating the effectiveness and credibility of the suggested approach in providing the optimal solution for practical industrial planning.

References

S. Torkaman, S. M. T. F. Ghomi, and B. Karimi, “Hybrid simulated annealing and genetic approach for solving a multi-stage production planning with sequence-dependent setups in a closed-loop supply chain,” Appl. Soft Comput., vol. 71, pp. 1085–1104, 2018, doi: https://doi.org/10.1016/j.asoc.2017.10.019.

C. A. Studies, “Numerical Optimization Approach for Solving Production Planning Problem Using Python language,” Cent. ASIAN J. Math. THEORY Comput. Sci., Jan. 2022, Accessed: Oct. 01, 2025. [Online]. Available: https://www.academia.edu/86744677/Numerical_Optimization_Approach_for_Solving_Production_Planning_Problem_Using_Python_language

U. M. Diwekar, “Introduction to Applied Optimization,” Springer, vol. 22, 2020, doi: 10.1007/978-3-030-55404-0.

H. Missbauer and R. Uzsoy, “Optimization Models of Production Planning Problems,” Int. Ser. Oper. Res. Manag. Sci., vol. 151, pp. 437–507, 2011, doi: 10.1007/978-1-4419-6485-4_16.

J. A. E. Andersson, J. Gillis, G. Horn, J. B. Rawlings, and M. Diehl, “CasADi: a software framework for nonlinear optimization and optimal control,” Math. Program. Comput., vol. 11, no. 1, pp. 1–36, Mar. 2019, doi: 10.1007/S12532-018-0139-4/METRICS.

C. Brown, A. Abdelfattah, S. Tomov, and J. Dongarra, “Design, Optimization, and Benchmarking of Dense Linear Algebra Algorithms on AMD GPUs,” 2020 IEEE High Perform. Extrem. Comput. Conf. HPEC 2020, Sep. 2020, doi: 10.1109/HPEC43674.2020.9286214.

M. Antoniou and G. Papa, “Evaluation of Parallel Hierarchical Differential Evolution for Min-Max Optimization Problems Using SciPy,” Lect. Notes Comput. Sci. (including Subser. Lect. Notes Artif. Intell. Lect. Notes Bioinformatics), vol. 13627 LNCS, pp. 84–98, 2022, doi: 10.1007/978-3-031-21094-5_7.

A. Danial, “Python for MATLAB Development: Extend MATLAB with 300,000+ Modules from the Python Package Index,” Python MATLAB Dev. Extend MATLAB with 300,000+ Modul. from Python Packag. Index, pp. 1–700, Mar. 2022, doi: 10.1007/978-1-4842-7223-7/COVER.

S. Chen, J. Fang, D. Chen, C. Xu, and Z. Wang, “Adaptive Optimization of Sparse Matrix-Vector Multiplication on Emerging Many-Core Architectures,” Proc. - 20th Int. Conf. High Perform. Comput. Commun. 16th Int. Conf. Smart City 4th Int. Conf. Data Sci. Syst. HPCC/SmartCity/DSS 2018, pp. 649–658, Jan. 2019, doi: 10.1109/HPCC/SMARTCITY/DSS.2018.00116.

L. H. Tao Wu, “A supervised learning-driven heuristic for solving the facility location and production planning problem,” Eur. J. Oper. Res., vol. 301, no. 2, pp. 785–796, 2022, doi: https://doi.org/10.1016/j.ejor.2021.11.020.

N. S. Gates, D. C. Hill, B. W. Billings, K. M. Powell, and J. D. Hedengren, “Benchmarks for Grid Energy Management with Python Gekko,” Proc. IEEE Conf. Decis. Control, vol. 2021-December, pp. 4868–4874, 2021, doi: 10.1109/CDC45484.2021.9683406.

E. B. M. Bashier, “Practical Numerical and Scientific Computing with MATLAB® and Python,” Routledge, 2020, [Online]. Available: https://www.routledge.com/Practical-Numerical-and-Scientific-Computing-with-MATLABr-and-Python/Bashier/p/book/9780367076696?srsltid=AfmBOorc1b0dxC_l-AQc0OQfqkrLz9D18HfYQQEAJPXljb-swQJylGct

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 50sea

This work is licensed under a Creative Commons Attribution 4.0 International License.